Weather Protection

All hoses are affected by weather conditions, sunlight, cold and moisture. Sunlight and cold harden the exterior of the hose, causing small cracks when the hoses flex. Moisture seeps into the cracks, freezing and expanding the next time the temperature drops below the freezing mark. As the cracks expand the moisture reaches the reinforcement of the hose, causing wire braiding to rust and cotton braid to rot.

The next time fluid pressure in the system peaks you have a hose failure, fluid on the ground, down time, extra expense and an upset customer because of another delay. Protecting a new hose with sleeve from the effects of weather may seem like extra expense, but in the long term it leads to savings.

Abrasion Protection

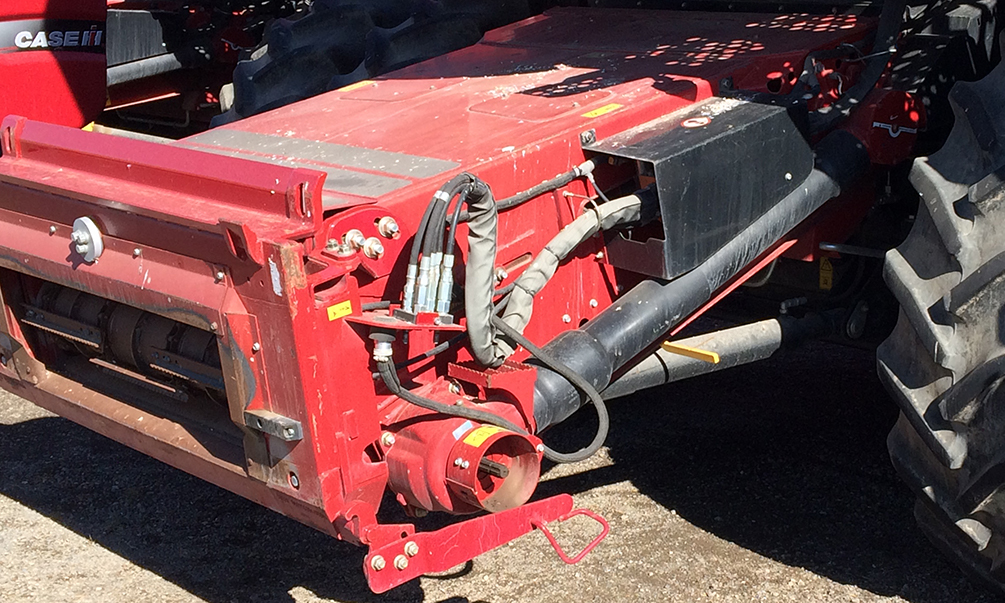

Many hoses on construction equipment are exposed to abrasion, some from rubbing against other parts of the machine. Others may have material falling on them during the operation of the equipment. Hoses used for loading and unloading tankers are pulled on and off the truck, pulled on the ground to connect to the truck and then pulled to the loading connection. The loading areas are covered by abrasive crushed rock or concrete causing wear on the cover of the hose.

Protective Sleeve reduces the damage caused by sharp edges on the hose racks and trays on the truck. Protective Sleeve also prevents wear and damage caused by hoses dragging on the gravel and concrete. Hoses carried on the exterior of the truck are exposed to intense weathering due to their exposure to the elements while on the road – water, salt, gravel and flying debris.

The combination of weathering and abrasion shortens the life of hose and increases the possibility of dangerous spills. Protective Sleeve prevents all these factors, extending the life of your hoses and improving safety and service.